Bamboo for social housing? Base Bahay shows us how it can be done.

“I am tired, really tired, of hearing people say bamboo is the timber of the poor,” Luis Lopez, an engineer who hails from Colombia, made this point during the Artkitektura Festival 2018. In his home country, he oversaw the projects of award-winning architect Simón Vélez, making sure that the acrobatic sweeps of bamboo arches, overhangs, and domes were structurally sound. In 2014, Lopez moved to the Philippines to continue his research on the applications of bamboo in social housing with Base Bahay.

No material is exclusive to the rich or the poor. Looking around Metro Manila, one can see iron and cement present in the glass-sheathed skyscrapers of central business districts as well as the patchwork walls and roofs of informal settlements. The poverty lies not in the material, but in the lack of refinement from the available technology used.

The main reasons why the impoverished use bamboo as a building material more often, especially in the countryside, are: ease of accessibility, and fast replenishment. Particular species of bamboo can grow at the rate of 91 cm per day. Meanwhile, the Dendrocalamus asper species in the Philippines can grow at the rate of 10 cm per day. In fact, bamboo is deeply entrenched in our culture. Our prime example of vernacular architecture, the bahay kubo, is made of it. In our creation myth of Malakas at Maganda, the first man and woman emerged from the hollow center of bamboo.

READ MORE: Out-of-school youth turned masons tasked to conserve Paco Park

Bamboo is a grass that thrives in tropical and sub-tropical areas. The only continents that do not have native bamboo are Europe and Antarctica. Both timber and bamboo are made of cellulose but their anatomies are different. Unlike trees which grow radially and whose strongest portion lies at the core, also called the heartwood, bamboo only grows vertically one node at a time once poles reach their maximum diameter. Also, bamboo’s strength lies in its circumference.

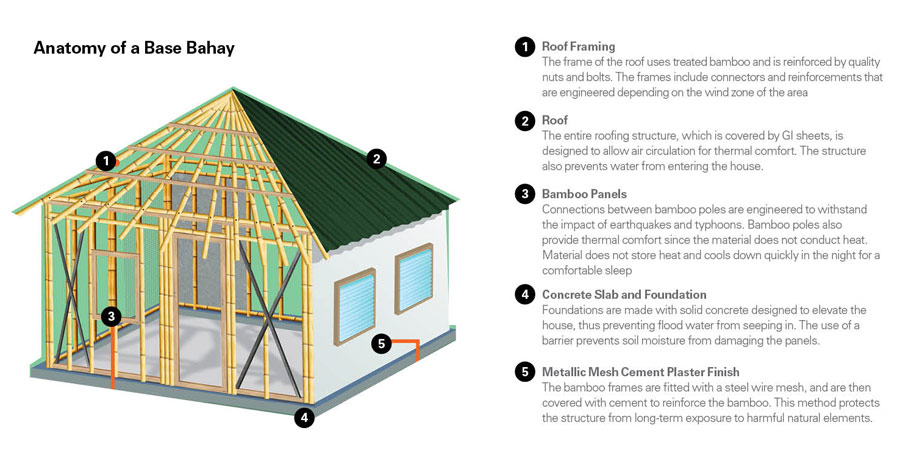

“It’s almost like reinforced concrete,” said Lopez. “Nature solved the problem of bending millions of years ago by putting more ‘rebars’ in the perimeter of bamboo so it is flexible in the wind.” As bamboo is dried and treated, the formation of small cracks between two nodes is normal. This is just the natural consequence of a difference of density of the exterior and interior of bamboo, at about 900kg/sqm and 200kg/sqm respectively. A 50-centimeter cut of bamboo can resist up to 20 tons of compression, meaning a big truck can rest on four poles without breaking. A 3-meter cut of bamboo, the usual length used for housing construction, can withstand about a ton of load.

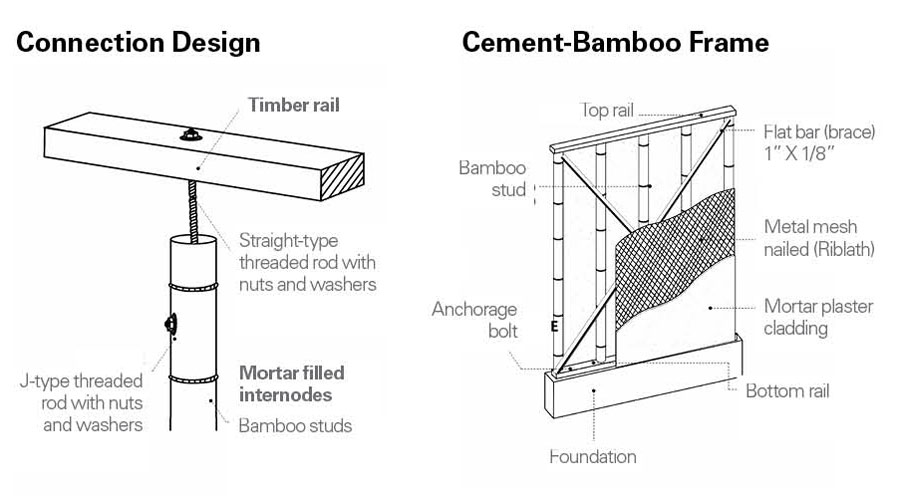

When Lopez was requested to begin the social housing initiative in the country, he immediately referred to bahareque, a traditional Latin American construction system in which basket-like frames of bamboo poles are set on the ground and plastered with mud or clay. The system has been studied and developed by through the years, and is now covered by the Colombian building code.

Research from different groups and universities has proven bahareque’s resistance of earthquakes, a daily occurrence in countries lying along the Pacific Ring of Fire. However, on top of seismic shifts and heavy rainfall, the Philippines experiences another kind of environmental threat uncommon in Columbia—typhoons with wind speeds over 200 kph.

In 2012, with the Base Bahay team at U.P. Los Banos, Lopez endeavored to test bahareque houses in the Philippine climate. They designed models using our local bamboo or kawayan tinik with ISO-standard walls and connections. Since a wind tunnel test was way over their budget, the team decided to utilize a real typhoon.

Three houses were set up in Ginubatan, Albay, in 2013. One house, built by Lopez, utilized all the proposed reinforcements and bolts for the bamboo frames which were protected by a cement shell. Another house experimented with laminate sawali instead of concrete. A third house was left to the discretion of local builders, who were shown full specifications yet value engineered the model with less bolts and fasteners. Then, in July 2014, Typhoon Glenda hit, with the eye of the storm crossing the site.

READ MORE: 5 public transit systems the Philippines can learn from

The weather station, which the team set up beside the houses, was felled by Glenda with the last recorded wind speed at 185 kph. Surrounding weather stations noted maximum speed at 220 kph. A PAGASA Resiliency Study recorded that bamboo houses collapse in wind speeds over 100kph while concrete hollow block (CHB) houses collapse at 220 kph.

The bahay kubos near the site were blown down, but the three model houses remained standing after the storm with slight damage only on the house built under specification. The three test houses also withstood collapse during Typhoon Ruby which arrived December of that year with over 200 kph wind speeds. Base Bahay then applied for Accreditation of Innovative Technologies for Housing (AITECH) with the National Housing Authority in 2015.

Since then, Base Bahay has completed 400 social housing units around the country in collaboration with organizations like Habitat for Humanity and Gawad Kalinga. Single-storey residences have floor areas ranging from 24 sqm to 30 sqm. There is even a two-storey model with a floor area of 55 sqm. “But our model goes beyond building bamboo houses. When you’re in a country where bamboo grows everywhere, you give farmers jobs. In the process, we educated them on how to select, harvest, treat, and transport bamboo,” added Lopez.

Today, there are three bamboo treatment plants set-up in Negros Occidental, Tarlac, and Bukidnon processing a total of 4000 poles per month. It takes about a month an a half to build a duplex hose. Around 2000 people have been given homes and 1000 jobs were generated through the bamboo treatment and farming facilities. The foundation is currently working on their most ambitious project yet: over 500 housing units in Silay, Negros Occidental.

With the local low-cost housing backlog at 5.5 million, the Base Bahay team has their work cut out for them. It is well and good that our local bamboo weathered the storms and has finally been given its big break. ![]()

This article first appeared in BluPrint Vol 2 2018. Edits were made for Bluprint online.

Images courtesy of Base Bahay